APPLICATIONS

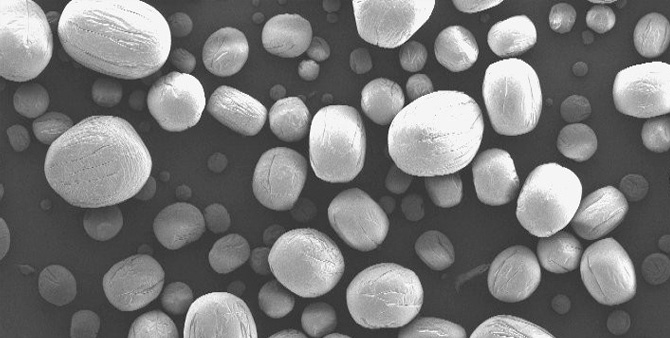

Pd (II) EnCat™ 30

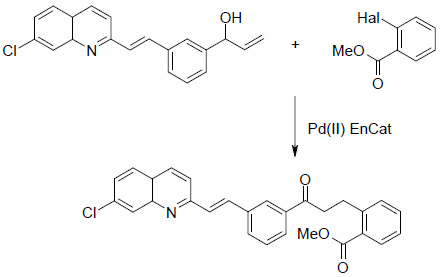

Heck Coupling

Montelukast Intermediate:

- Recycles possible

Alkene, Pd EnCat™ (5 mol% Pd), Bu4NCl (1 eq) and NaHCO3 (2.4 eq) were added and purged with N2. Degassed acetonitrile was added followed by aryl halide and the reaction mixture stirred at reflux under N2 for 5 h. The reaction mixture was filtered to remove the EnCat, washed with water and concentrated to dryness to give a crude yield of 91%.

The Pd EnCat™ route gives a significantly higher crude isolated yield than the current process.

- These high conversions can be attained at a lower Pd loading (1mol% versus 3.5 wt% Pd)

- The Pd EnCat™ catalyst is easy to remove by simple filtration

- The EnCat™ process can deliver an extra output of around 0.4 kg per 1.0 kg input

- Relatively low Pd leaching

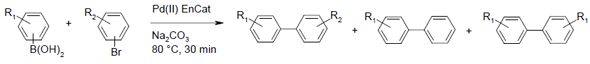

Suzuki Coupling

| Catalyst | %Yield A | %Yield B | %Yield C | Pd (ppm) inCrude product |

| 5% Pd/C, 2.50 mol% Pd EnCat™ 30, 2.50 mol% Pd EnCat™ 30, 0.25 mol% |

87 97 >99 |

13 <1 <1 |

0 <1 <1 |

56 14 9 |

- Low homo coupled products C

- Low palladium leaching

- Pd charge reduced by 10 times

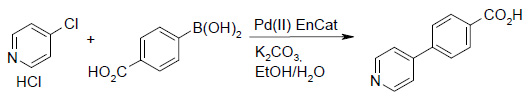

4-Pyridin-4-ylbenzoic Acid:

- 85% yield

- Pd EnCat system gives 30x rate using Pd(OAc)2

- Successful scale up

- Catalyst easy to charge and filter, with low cake resistance

- Excellent reaction control - removing catalyst stops the reaction